September 8-11, 2025

Bush Convention Center - Midland, TX

This September, oil & gas professionals from all over the world will gather in Midland, Texas for four days of continuing education, technical sessions, panels, and more. Join us as we share new insights and emerging trends, explore best practices, and discuss the latest advancements in sucker rod pumping technology and optimization. You'll discover new and leading products and services in the nearby exhibitor hall, and enjoy ample opportunities to network with individuals from diverse professional backgrounds.

Call for Abstracts

Presentations by operators and innovators are key elements of a successful workshop. If you have improved or optimized production, reduced operating costs or failures, overcome challenges, or discovered new and innovative techniques or products related to sucker rod pumping, we invite you to submit an abstract for consideration as a technical presentation at the upcoming Sucker Rod Pumping Workshop. Contributing knowledge and experience is a valuable and critical opportunity to do your part to ‘give back’ and help ensure generations of ongoing success with sucker rod pumping as a form of artificial lift.

Abstracts requirements and conditions

- Abstracts must be a minimum of two hundred fifty words with a maximum of five hundred words.

- Topic must be sucker rod pumping related or relevant to the artificial lift industry.

- Abstract deemed to be commercial only, will be rejected.

- Abstracts about research, lab testing, manufacturing processes, and field trials are acceptable.

- All abstract content accepted will be public and available for access on ALRDC’s website.

- Presentations will be grouped by topics for review by the sucker rod workshop committee.

- The use of company names and logos is prohibited in the title.

- The abstract shall be professional in nature and refrain from social or political statements.

Abstract submissions should contain the following

- Objective / Scope

- Methods,

- Procedures

- Processes

- Results

- Observations

- Conclusions

- Authors names and contact details

Abstract submission will close July 14, 2025

Program Chair

Anthony Allison

Senior Artificial Lift Advisor, Occidental Petroleum

Registration

2 day conference – $650 early bird / 700 regular

1-day conference – $350 / 400 regular

1-day class – $400

2-day class – $700

Sponsorship Opportunities

A limited number of Sponsorship opportunities are now available for the upcoming Sucker Rod Pumping Workshop. Sponsorship packages include complimentary workshop registration and recognition as an event sponsor on promotional materials leading up to, and during, the workshop.

Event sponsors are recognized in various ways, including:

Logo and/or links on ALRDC website, online registration page, and email campaigns

Logos on workshop signage, presentation slides, and other materials

Announcements during workshop classes and sessions

Logos, links, and/or tags on LinkedIn and other social networks

Schedule

Continuing Education Classes

September 8 | 8:00am to 4:30pmSeptember 9 | 8:00am to 4:30pm

Technical Sessions

September 10 | 8:00am to 4:35pm

September 11 | 8:00am to 4:35pm

Keynote

September 10 | 12:15pm

Exhibit Hall

September 10 | 7:30am to 5:35pm

September 11 | 7:30am to 5:30pm

Registration/Information Table

September 8 | 7:30am to 4:30pmSeptember 9 | 7:30am to 4:30pm

September 10 | 7:30am to 4:30pm

September 11 | 7:30am to 12:00pm

Live Stream Links

Streaming sponsored by RTS

Contact ALRDC

Prior to the first day of the workshop, please contact us by email at info@alrdc.com with any inquiries.

Keynote

Wednesday, September 10th | 12:15 PM

The ALRDC proudly presents our keynote speaker for the 2025 Sucker Rod Pumping Workshop

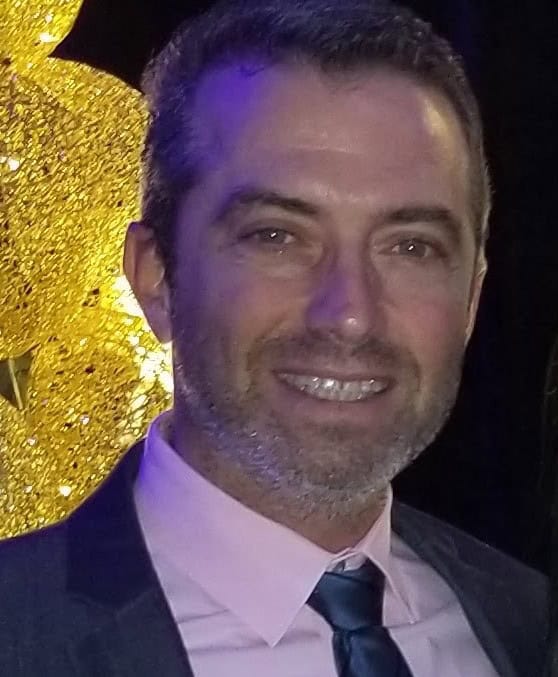

Paul Mahoney, a prominent figure in the oilfield industry.

Paul Mahoney is president of the Production & Automation Technologies business at ChampionX and has led our global artificial lift business since 2012. Before joining Apergy, Paul was president of Dover Artificial Lift, part of Dover Energy. He also served as Chief Operations Officer for Dover and as senior vice president of global sales and operations for Dover Artificial Lift.

In May 2023, Paul was elected to the Board of Directors of Chart Industries, Inc. an NYSE-listed global manufacturer of highly engineered equipment servicing multiple market applications in energy and industrial gas, and he serves as a member of the Nominations and Corporate Governance Committee and the Compensation Committee.

Before joining Dover Energy, Paul held a variety of sales and management roles at Emerson Electric Company, including vice president and general manager of the Analyzers Group, vice president, global sales and operations for the Analytical Group, and director of sales for the process automation group.

Paul received a bachelor’s degree in electrical engineering and physics from the University of Buffalo and an MBA from Seattle University.

Continuing Education

This year's Sucker Rod Pumping Workshop offers a variety of one and two day courses that oil and gas operators and producers with every level of experience are sure to find valuable.

Incomplete Fillage - Gas Interference, Fluid Pound, Blocked Intake

Monday, September 8

Abstract: “LONG AND SLOW” OR “SHORT AND FAST” is NOT the way to go! The way to go is to apply recommended practices to operate your wells, do not operate your wells with incomplete pump fillage more than 2% of the time. When a failure occurs then identify the cause and strive to prevent a repeat occurrence of the failure in the future. The three causes of incomplete pump fillage can be accurately diagnosed by using representative dynamometer and fluid level surveys. The magnitude of the pump loads w/ respect to the zero load line, Fo from the Fluid Level, and the Fo Max Load can be used to identify the cause of incomplete pump fillage. The pressure inside the pump chamber is a function of plunger travel and compressibility of fluid in the pump. Sucker rod pumps intake well fluids through the standing, SV, and discharge fluids into the tubing through the traveling, TV.

Gas pumped into the tubing can be detrimental to the operation of the sucker rod pumping system. No pump action can occur when the tubing fluid gradient becomes too light because too much gas is pumped into the tubing. Low producing efficiency and increased rod-on-tubing wear are common problems created by gas interference. Use of back pressure and/or gas separation may be required to increase tubing fluid gradient in order to maintain pump action. Proper gas separator selection requires that pump displacement not exceed gas separator liquid capacity. Casing size determines the maximum size gas separator than can be installed in a well so that annular gas flow will not reduce the liquid throughput efficiency by restricting liquid inflow into the separator chamber. A specific design and size of a gas separator determines the maximum liquid rate that will not drag gas into the pump intake. This rate is defined as the Separator Liquid Capacity. If the pump displacement exceeds the separator liquid capacity, then gas separation will fail and the producing efficiency of the well will be poor.

Low Pump intake pressure in conjunction with incomplete pump fillage cause the pump plunger to suddenly slow on the down stroke quickly transferring the fluid load opening the TV resulting in shock loads throughout the entire pumping system. The shock loading can cause increased rod-on-tubing wear, pump wear, severe rod loading changes and pumping unit vibration even to the extent that the vibration can be visually observed and oftentimes even heard. These changes in rod loading on the downstroke also affect the pumping unit balance and motor power requirements. Longer equipment life will be experienced by the pump, rods, tubing and pumping unit system if the pump does not operate with incomplete pump fillage more than 2% of the time. Sucker rod lifted wells having a pump capacity which exceeds the production rate of the well would operate more efficiently and at a lower cost with a device that reduces the amount of pumping unit operating time. Operating the pumping system with a pump barrel full of liquid will result in high efficiency and longer equipment life.

Course Agenda

- Introduction

- Surface and Pump Card Reference Loads

- Incomplete Pump Fillage

- Simulation of Downhole Gas Separator Performance

- Downhole Gas Separation

- Gas Separation – Horizontal Wells

- Gas Locked Pumps are NOT Gas Locked

- Equivalent Gas Free Pump Fillage Line

- Use QRod with the Pump Slippage Equation to Design Pump Clearances

- Tubing Anchors Can Restrict Production and Reduce Pump Fillage

- Controlling Runtime

Course Instructors

Gustavo Fernandez holds a degree in Petroleum Engineering from The University of Zulia in Venezuela. With over 20 years of experience, most of his career dedicated to production optimization for wells with Artificial Lift Systems, Mr. Fernandez has authored many research works/technical papers for numerous organizations. He has presented seminars and talks throughout the world on the efficient operation, optimization, and troubleshooting of oil and gas wells. Gustavo has worked in many countries in Latin America, Middle East and also the

USA, which has allowed him to work and share with colleagues from multiple cultures in different environments.

Mr. Fernandez holds the position of Vice-president of Engineering for Echometer Company in Wichita Falls, TX and also provides training and consultation in performing well analysis to increase oil and gas production and reduce operating cost using Echometer technology.

O. Lynn Rowlan education includes a Bachelor and Masters of Science degree in Civil Engineering graduating in 1976 from Oklahoma State University. Mr. Rowlan was registered as an Oklahoma Professional Engineer July 1980 and received: the 2000 J.C. Slonneger Award from the, SWPSC, SW Petroleum Short Course Association, Inc; the 2010 SPE Distinguished Production Operations Award; the 2011 SWPSC Crawford Service Award; and the SPE 2020 SPE Legend of Artificial Lift Award; and the recipient of the 2024 James N. McCoy Lifetime Contribution Award from the SWPSC.

Beginning in September 2019 Mr. Rowlan retired from full time employment and now works as a consultant. Prior to retiring Mr. Rowlan held the position of Vice-president of Engineering for Echometer Company in Wichita Falls, Texas. Prior to August 2000 he held the position of Artificial Lift Consultant for Amerada Hess Corporation in Houston, Texas.

During the 45 years of experience in the Oil & Gas industry Mr. Rowlan has authored more than ninety research works/papers for the SWPSC, ASME, the Solution Mining Research Institute, the Artificial Lift Research and Development Counsel, the Russian Oil & Gas Technologies Magazine, the Canadian Petroleum Society and the Society of Petroleum Engineers. He co-authored a book for gas well production optimization “Gas Well Deliquification” holds a US Patent # 6,634,426 on Plunger Lift Analysis. His primary interest is to advance the technology of all artificial lift production systems and to present seminars and talks on the efficient operation, analysis, optimization, and troubleshooting of oil and gas wells.

Rod Pump Fundamentals & Dynamometer Analysis

Monday, September 8

Course Agenda

- Pumping Unit

- Rods

- Pump

- BHA

- Dynagraph Interpretation

- Automation

- Design

Course Instructors

Matt Raglin

Gary Abdo

Gary Abdo is a seasoned reciprocating rod lift expert specializing in sucker rod design, rod guides and optimization for rod lift systems. With almost 30 years of experience in the sucker rod industry, Gary has dedicated his career to enhancing the efficiency and reliability rod pumped wells.

He holds a degree in mechanical engineering from Oklahoma State University, where he developed a strong foundation in mechanical engineering principles. Throughout his career, Gary has worked with various oil and gas companies, contributing to innovative solutions that address common challenges in rod lift operations.

In addition to his technical expertise, Gary is passionate about education and knowledge sharing. He frequently conducts workshops and training sessions aimed at equipping engineers and technicians with the skills needed to optimize sucker rod systems.

Managing Production Chemical Treating Programs

Tuesday, September 9th

Business Impact

This course can be attended by Operational personnel that are seeking a better understanding of their chemical program, as well as by chemical and service vendors that are seeking a deeper understanding of the production chemical business and desire additional training in those technical areas.

Course Description

This course will present an overview of production chemicals, their selection processes and will present overviews to better understand the tests used to monitor their performance.

Summary:

Chemicals can aid in minimizing disruptions in the production cycles of a producing well. Chemicals can aid in the reduction of a corrosion rate; they can assist in the enhancement of oil and water separation; they can reduce the amount of solids produced from, or injected into, wells; they can even assist in the optimization of natural gas production. While they can have many positive economic attributes, chemicals can also have an impact on our safety and environmental performance. However, for chemicals to be effective, the field conditions must be correctly evaluated, and the proper chemical identified and applied. This course will present an overview of production chemicals, the testing processes utilized for the selection of a product and will present the attendees with an understanding of the analytical tests used to track and monitor their performance.

Learning Outcomes

Upon completion of the course, the attendees will have a better understanding of the screening tests utilized for the selection of production chemicals and the analytical testing used to monitor, and optimize, their performance. Attendees will also gain valuable knowledge on what questions to ask of their chemical suppliers to ensure the proper screening tests and monitoring tests have been, or are being, performed.

Training Method

This course is presented in person, with break-out sessions and hands-on exercises utilized to reinforce the lecture portion of the class.

Who Should Attend?

This course is designed for anyone managing production chemical programs. Beginners to experienced technicians/engineers can attend this class. During break-out and class discussion sessions, information exchanged between attendees can benefit all levels of experience.

Prerequisites

A basic understanding of oilfield production equipment will be advantageous for this course, but not necessarily a requirement.

Course Outline

- Overview of the Discovery/Survey Process – Identification of Field/Well Challenges

- Screening and Selection of Demulsifiers

- Mineral Scale Formation and Inhibition Basics

- Suspended Solids

- Overview of Corrosion and Corrosion Inhibitors

- Microbiologically Induced Corrosion – Identification, Treatment and Monitoring

- Organic Deposits

- Structuring Chemical Reviews

Course Instructor

Becky began her career in the Oil and Gas Industry in 1981, focusing on equipment design, corrosion control, oil field chemicals, water analysis interpretation, non-destructive testing, and the application/inspection of internal and external coating systems. Becky has her B.S. in Chemistry from Angelo State University, graduating Magna Cum Laude in December 1980. She has worked 23 years for oil-field chemical companies, 14 years for a major oil company as their Chemist/Corrosion control specialist, 2 years as an independent Consultant – where she served as an Expert Witness in four lawsuits. She has one patent during her time with the industry: “Repair and Restoration of Above Ground Storage Tanks.” She is currently serving as a Consultant for Martin Water Labs, Inc., focusing on failure analyses, mineral scale, and technical training.

During her time with chemical companies, Becky worked in the manufacturing/quality control aspect of production chemicals, technical service division for production chemicals and recently worked as a Technical Trainer for in-house and Customer Technical Training programs. Becky has been a NACE/AMPP member since 1983 and has served on multiple technical committees and has served in every position within the local section. She has published three (3) technical papers through the Texas Tech Southwestern Petroleum Short Course (SWPSC), held annually in Lubbock, TX, and has presented multiple pre-conference technical training courses pertaining to production chemicals, basic corrosion technology, mineral scale prevention, failure analyses and analytical testing.

She was recently awarded the Duane A. Crawford Service Award by the Southwestern Petroleum Short Course (2019) in honor of her volunteer service to that conference. She was the recipient of the 2023 Slonneger Award for her outstanding contributions to Artificial Lift.

Root Cause Failure Analysis

Tuesday, September 9th

Abstract: Root cause failure analysis is the key to identifying appropriate solutions to problems with single well repairs as well as systemic problems within a lease, asset, or specific well population. Establishing a comprehensive RCFA process with the appropriate foundations is essential to ensuring producers are maximizing the knowledge gained from historical failures. This course presents the key items needed to create and maintain a proper RCFA program. It will cover the foundations of a proper program, the important information needed for a proper RCFA to be conducted, recognition of failure mechanisms for the different components in an SRP system, as well as some possible solutions for those failures.

Course Outline

Overview (Courtney Richardson – Oxy)

– What is RCFA?

– Why is it important?

– Foundations of RCFA

Key points for proper RCFA

– Surveillance/Operational strategy prior to failure (Chris Cavazos – Oxy)

– Understanding chemical Program (Kristen Barnes – Apache)

– Methods of application

– Tracking

– Effects of improper inhibition

Understanding SRP components and how they fail – 3 hours

– Rods (Scott Malone – TRC)

– Tubing (Anthony Allison – Oxy)

– Pumps (Rickey Rodrick – Champion X)

Example RCFA scenarios (Courtney Richardson – Oxy)

RCFA data analysis/action items (Courtney Richardson – Oxy)

– Accountability for action items

– Identifying systemic issues

Course Instructors

Courtney has been with Oxy since 2016. Her early career experience with data management for well servicing operations triggered deep interest in understanding failure data. This guided her path to the QA/QC Artificial Lift team which is heavily involved in RCFA process standardization. A primary function of QA/QC is understanding lift equipment through its life cycle, from manufacturing to failure mode. This requires a heavy collaboration with manufacturers, engineers, lift design experts, and well servicing teams to increase run times by learning how to mitigate specific failure mechanisms. She is a proponent of standardizing the methods by which data is captured in order to reap the full benefit of analytics and make sound operational decisions based on data.

Scott’s primary responsibilities with TRC are Rod String Design (RODSTAR) for (Steel, FG and continuous rod) and make rod guide recommendations. He trains string designers to provide consistent designs from TRC. He provides written Failure Analysis for sucker rods for various operators. He participates in failure meetings several times a month to support our product, troubleshoot repeat failures and recommend solutions. Scott has also served on the API 11B committee for over ten years, and taught Failure Analysis and Corrosion Inhibition classes SWPSC, ALEOC and customer locations for about 20 years.

Rod Design and Rod Guide Fundamentals

Tuesday, Sept 9th

Rod Design – Sara Million

This course will discuss basic sucker rod design practices and how to optimize designs while utilizing modern rod design programs in deviated and vertical wells.

Rod Guide Fundementals – Esteban Oliva

This module will cover basic concepts of the Rod guides for sucker Rod Lifting systems. An initial walk through the historic progression of the initial attempts for guiding and the major challenges found. The evolution to polymeric solutions and the current state of the guiding industry. An overall revision of the guiding goals to prevent rod and tubing wear, improve stress distribution and fluid dynamics in the sucker rods.

Learning Objective: To get an overall understanding of the rod guides in the industry, their challenges and the available strategies to solve the problems targeted in rod lift systems.

Course Outline

- Pumping Unit selection

- Downhole pump types/limitations

- Sucker Rod Metallurgy/Proper selection of rods

- Determining Rod Guide placement

- Sinker Bars vs. Sinker Rods

- Setting Program Defaults

- Adding Custom Rods and Pumping Units into the software

- How to read and understand the Design Output Reports

- Recommended Practice for designing steel and fiberglass rod strings.

Course Instructors

Sara Million holds a Bachelor of Science in Ocean and Coastal Systems Engineering from Texas A&M University where her love for oil and gas began. She is a Reciprocating Rod Lift Engineer at Liberty Lift with seven years of experience in the Permian Basin and Bakken. She began her career in Bakersfield with Weatherford and rotated between gas lift, sucker rods, continuous rod, rod pumps, capillary, pumping units, jet pumps and sucker rod failure analysis.

She currently uses the knowledge she gained by moving around different AL operations teams in multiple regions to increase run times, reduce failures and optimize reciprocating rod lift systems. She is enthusiastic about understanding every aspect of a problem or situation and helping to construct a solution. When she is not focusing on RRL optimization, she spends her time on hobbies that keep her active and outdoors.

Technical Sessions

September 10th and 11th

$550

Wednesday, September 10

8:00 – 8:15

Opening Remarks

Event Chairperson Joseph A. Norman, FluidLevels.com

Session 1: Downhole Modeling Studies

8:15 – 8:45

Horizontal Well Deviated Downhole Data Acquisition Project Update

Dr. Victoria Pons, WellWorx Energy

Lynn Rowlan, Echometer

Dr. Tony Podio,

Michael Romer, ExxonMobil

Robert Valadez, Marathon

Walter Phillips, Wansco

Wyatt Tubb, ETA

Clarence Foytik, MicroSmart

8:45 – 9:15

Optimizing Rod Pump Performance Using High Frequency, High Resolution Pressure Data At The Wellhead

Tokunosuke Ito, TOKU Systems

9:15 – 9:45

Automated Viscous Damping Correction and Optimal Inferred Production Calculation

Dr. Victoria Pons, WellWorx Energy

Jeremy Gomes, WellWorx Energy

9:45 – 10:15

Morning Break

Session 2: Dynamometer Card

10:15 – 10:45

Sensorless Downhole Pump Card Approximation

Simon Jagers, Samotics

10:45 – 11:15

A New Method of Pump Stroke Position Measurement

Walter Phillips, Wansco

11:15 – 11:45

Using A Hydraulic Sheave Lock Versus Traditional Methods to Safely Lock Out A Beam Pumping Unit

Kurt Richard, ATABEC Safety Lock Corp.

11:45 – 12:15

Lunch Break

12:00 – 1:00

Keynote

Doug Hebert, Liberty Lift Solutions

YouTube LiveStream

https://youtube.com/live/w3wsYkS7TXA?feature=share

Linkedin Stream

https://www.linkedin.com/events/day1-alrdcrodpumpworkshopkeynot7097623347693318145/theater/

Session 3: Rod Tubing Pumping Unit Technologies

1:00 – 1:30

Avoiding Environmental and Financial Impact of Stuffing Box Leakage

Dr. Victoria Pons, Pons Energy Analytics

Rob Harrison, Well Site Guard Ltd.

Elaine Lang, Well Site Guard Ltd.

1:30 – 2:00

Wireless Sensor Technology to Monitor Rod Rotator Performance

Terry Treiberg, ChampionX

Brandon Furr, ChampionX

2:00 – 2:30

Sucker Rod Connections Reliability Improvement Via Diagnostics of Power Tongs

Andres Alam, Tenaris RODS

Liliana Valdebenito, Tenaris RODS

Esteban Oliva, Tenaris RODS

2:30 – 3:00

Afternoon Break

Session 4: Automation Controllers

3:00 – 3:30

The Ken Well Manager: An Adaptive Controller for Dynamic Deviated Wells

Dallas Barrett, WellWorx Energy Solutions

Russell Messer, WellWorx Energy Solutions

3:30 – 4:00

Advanced Variable Frequency Drive Control: Optimizing Against Incomplete Fillage

Tim Hinojosa, Occidental Petroleum

Biplav Chapagain, Occidental Petroleum

4:00 – 4:30

A Discussion of Rod Lift VSD Control Parameters, Setup, and Configuration for Most Efficient Operation Under Varying Operating Conditions

Peter Westerkamp, Lufkin Industries

Thursday, September 11

Session 1: Rod Tubing Pumping Unit Technologies

8:00 – 8:30

Convert to Rod Lift Sooner – Long Stroke Pumping Units

Spencer Evans, Liberty Lift Solutions

Joe Calhoun, Liberty Lift Solutions

8:30 – 9:00

Case Study Comparing Wall Loss Measurements Due to Sucker Rod Wear, Erosion and Corrosion on Boronized Versus Untreated OCTG Production Tubing in a Rod Pumped Oil Well

Craig Zimmerman, Bluewater Thermal Solutions

9:00 – 9:30

Boron-Carbide Treated Couplings Improve Rod Lift Efficiency in South Texas Wells

Bo Brooks, Chesapeake

9:30 – 10:00

Morning Break

Session 2: Separators BHAs

10:00 – 10:30

Innovative Design of a Packerless Gas Separator Design in ESP to Rod Pump Conversion

Luis Guanacas, OSI

Gustavo Gonzalez, OSI

11:00 – 11:30

Testing Hydraulic Tubing Anchors

Ryan Blair, Black Gold Pump

Bob Smithwa, Black Gold Pump

11:30 – 12:00

Lunch Break

12:00 – 1:00

YouTube Stream

https://youtube.com/live/QKdcoIwAEg4?feature=share

Linkedin Stream

https://www.linkedin.com/events/day2-alrdcrodpumpworkshop-panel7097973669439696896/theater/

Session 3: Dynamometer Card Modeling

1:00 – 1:30

A Closed Loop System To Improve Performance of Artificially Lifted Wells On Pump

Bob Berland, Energy Solutions Generator, LLC

1:30 – 2:00

Increasing Production by Using a Two Stage Filtration System: Case Studies in South Texas

Travis Wadman

Shivani Vyas, OSI

2:00 – 2:30

Sucker Rod Modeling in 4-D

Jim Robinson, Kepler Software Engineering, Ltd

Tom Mills

2:30 – 3:00

Afternoon Break

Session 4: Automation Controllers

3:00 – 3:30

Autonomous VSD Setpoint Optimization for Sucker Rod Artificially Lifted Oil and Gas Wells

Ian Nickell, ChampionX

3:30 – 4:00

Technical & Operational Challenges in Developing Unconventional Tight Oil ABH Field, India

Nakul Varma

Manish Kumar

4:00 – 4:30

Cloud Based Real-Time Monitoring of Tight Oil Field by Applications of Edge Gateway Device, Automatic Fluid Level Analyzer and Analytical Dashboards

Ravi Chandak, Cairn Oil and Gas, Ledanta Ltd

Nakul Varma

Kumar Manish Janardan Yadav

Sujit Jadhav

4:30

Closing Remarks

Rod Pumping Fundamentals and Dynamometer Analysis

Monday, August 28th | $400

This comprehensive course offers real-world training by industry experts for optimization, design and best practices. The training course will provide all attendees with an all-encompassing understanding of the rod pumped system to allow for improvements in optimization techniques to achieve additional production, runtimes, and minimized failures.

Course Outline

- Pumping Unit

- Rods

- Pump

- BHA

- Dynagraph Interpretation

- Automation

- Design

Course Instructors

Matt Raglin began working for Diagnostic Services (DSI) in 1985, traveling and analyzing rod pump wells first in the United States and later globally until it was purchased by Halliburton. In 1989, Raglin formed his first company, Reservoir Evaluation Services, which continued his work in the rod pump system analysis field. RES was sold to Wood Group in 1995.

From 1995 to 2001, Raglin was an independent consultant for rod pump analysis and design and he worked with many of the largest producers in the industry, including Shell, BP, Exxon, Occidental and Chevron. In 2001, Raglin began working for Lufkin Automation as the General Manager of Permian Operations. It was here he began a close working relationship with Dr. Sam Gibbs and Ken Nolen and was instrumental in helping design and introduced the industry to the SAM Controller, which is now used worldwide.

Raglin left Lufkin and formed Spirit Global Energy Solutions in 2008. Headquartered in Midland, the primary focus of Spirit Global was analyzing wells with portable dynograph and fluid level equipment. The company also provided remote analysis utilizing a SCADA host. Wanting to provide additional solutions to the industry, Raglin invented several patented downhole tools to mitigate gas and sand issues and a laser positioning device. Spirit Global also released the Genesis Controller, which is now known as the ChampionX Smarten Controller, under Raglin’s guidance. Spirit Global had offices in every producing basin in the United States as well as regional operations in Canada. The company was purchased by Dover Artificial Lift in 2013 and now operates as ChampionX.

Raglin formed WellWorx Energy in 2018 with a mission to offer in-person trainings and webinars focusing on rod pump principles and best practices as well as dynagraph interpretation. These education-based solutions were taken a step further and he began to design and patent the ToolWorx product line of downhole tools. Raglin currently holds 14 patents and his designs are focused on gas and sand mitigation efforts. The product line includes the Super Max System, the Helix Sand ByPass, the Halo, the Dominator and the ESP Gas ByPass with additional products planned for the future.

Seeing additional needs within the industry, Raglin purchased GreenShot LLC from Dr. Sam Gibbs and Ken Nolen. GreenShot is patented as the first fully permanent and automated fluid level system. It is also the only true ‘green’ system in existence, functioning without high-pressure nitrogen or C02 and instead utilizing the well’s naturaly-producing casing gas.

In the last 25 years, Raglin has taught hundreds of Rod Pump classes across the world. Throughout his career, Raglin has published more than a dozen technical papers and is partnered with multiple Texas universities to organize internships with field training as well as served as a guest lecturer to offer insight into the petroleum industry.

Jason Jones, ConocoPhillips

Kenneth B. (Ken) Nolen attended Texas A&M College and graduated in 1957 with a B.S. in Mechanical Engineering. Upon graduation, he joined Shell Oil Company as a Production Engineer. His career was temporarily halted for three years while he served in the U.S. Air Force as a Weather Officer at Dow Air Force Base in Bangor, Maine. Returning to Shell, he gained further experience in artificial lift as production engineering section head.

In 1970, he left Shell and teamed up with Dr. S. G. Gibbs to become co-founder and Vice President of Nabla Corporation, a high-tech services and manufacturing firm in Midland, Texas. While there, he pursued his career-long passion of optimizing production from artificially lifted wells. Lufkin Automation acquired Nabla in August 1997. Nolen continued his career as Technical Coordinator for the new firm until his retirement in 2002.

Retirement was short lived and he started working as an artificial lift consultant specializing in technical support and training. Again, Nolen and Dr. Gibbs teamed up in 2014 and formed GreenShot LLC, a company specializing in automated oil well fluid level technology. WellWorx Energy acquired GreenShot in 2018 and Nolen is currently employed by WellWorx as R&D Advisor.

Nolen has been a key contributor to the art and science of artificial lift his entire career. He was a co-developer with Dr. Gibbs of wellsite diagnostic methods (dynamometers, fluid level sounders and pump-off controllers) for sucker rod pumping systems. These diagnostic methods are widely used within the industry to remotely access data through automated continuously monitoring systems.

Nolen has been active in SPE his entire career and is a registered professional engineer emeritus in Colorado and New Mexico. He has eight patents, has written textbooks on artificial lift subjects and has written or co-written numerous technical papers to serve the industry. In the past 50 years, Nolen has taught more than 200 schools on artificial lift (mainly rod pumping technology) throughout the world.

Exhibit Hall

September 8th & 9th | 7:30 AM - 5:30 PM

Included with session registration

ALRDC's Sucker Rod Pumping Workshop returns this summer promising outcome-oriented courses and sessions offered in a variety of engaging formats designed to inform, equip, and inspire operators and producers.

To enhance learning opportunities for workshop attendees, a variety of leading and innovative solutions, products and services will be on display in our nearby exhibit hall, where participants are encouraged to browse during designated breaks. Representatives from oil and gas operating companies, manufacturers, suppliers, and service companies will be available to engage with and answer questions.

Interested in showcasing your company, products, or services at the upcoming Sucker Rod Pumping Workshop?

Sponsorships & exhibitor packages focus on creating opportunities for meaningful connections between artificial lift vendors and prospective buyers, through a variety of digital and traditional means. ALRDC's subscribed audience includes thousands of energy industry workers ranging from students to executive leadership, researchers, and inventors. The 2025 Sucker Rod Pumping Workshop venue can accommodate an audience of 250 production engineers, lease operators, foremen, superintendents, production managers, service providers, and students.

Diversity & Inclusion – Bridging the generation gap for a stronger industry

Thursday, August 31st | 12:00 PM

In our industry today, the workforce is comprised of no less than five generations, each of which thinks differently, learns differently, communicates differently and values different priorities. This is due to the environment each generation has developed and flourished in. In this panel discussion, our panelists will share their experience and views relating to work, life and interacting with other generations in both their personal and professional journeys. We hope this will bring insight and help our audience to relate with other generations, appreciate their input and value their contribution so we can all thrive and do our best for our industry.

Panel Members

Dr. Victoria Pons has served as ALRDC Vice President since 2020 and member of the ALRDC board since 2017.

Dr. Victoria Pons is also the Director of Research and Strategic Development at WellWorx Energy where she leads the research, planning and implementation of innovative new programs and products for WellWorx. As an industry SME, Dr. Pons has greatly contributed to the advancement of new algorithms for rod pump control and other forms of artificial lift.

Victoria is very passionate about Diversity and Inclusion and created a D&I Committee at ALRDC to help educate and enrich our industry.

Dr. Rajan Chokshi has over 35 years’ work-experience in artificial lift, real-time production optimization, software development, and management. His current work is on artificial lift optimization, multi-phase flow calculations, failure prediction, virtual flow meter, emission reduction, and competency management. Chokshi has worked for national oil companies, majors, independents, service providers and technology companies. He has co-authored over fifteen SPE papers, two patents, and has delivered several SPE webinars and training courses. Besides conducting professional workshops globally, he has taught at Texas Tech, Missouri S&T, U of Southern California and U of Houston. Twice selected as an SPE distinguished lecturer, he also volunteers on multiple SPE technical committees. Recently he was selected to serve on the ALRDC board of directors. Dr. Chokshi holds a Bachelor’s and Master’s in chemical engineering from the Gujarat University and IIT-Kanpur, India, and a Ph.D. in Petroleum Engineering from the University of Tulsa, USA.

Lynn Rowlan education includes a Bachelor and Masters of Science degree in Civil Engineering graduating in 1976 from Oklahoma State University. Mr. Rowlan was registered as an Oklahoma Professional Engineer July 1980 and received: the 2000 J.C. Slonneger Award from the, SWPSC, SW Petroleum Short Course Association, Inc; the 2010 SPE Distinguished Production Operations Award; the 2011 SWPSC Crawford Service Award; and the SPE 2020 SPE Legend of Artificial Lift Award.

During the 43 years of experience in the Oil & Gas industry Mr. Rowlan has authored more than eighty research works/papers for the SWPSC, ASME, the Solution Mining Research Institute, the Artificial Lift Research and Development Counsel, the Russian Oil & Gas Technologies Magazine, the Canadian Petroleum Society and the Society of Petroleum Engineers. He co-authored a book for gas well production optimization “Gas Well Deliquification” holds a US Patent # 6,634,426 on Plunger Lift Analysis. Beginning in September 2019 Mr. Rowlan retired from the position of Vice-president of Engineering for Echometer Company and now works as a consultant. His primary interest is to advance the technology of all artificial lift production systems and to present seminars and talks on the efficient operation, analysis, optimization, and troubleshooting of oil and gas wells.

Shivani Vyas is a Business Development Manager at Odessa Separator Inc. (OSI). She holds a Bachelor’s degree in Petroleum Engineering from Texas Tech University. Shivani firmly believes in innovation and giving back to the community. She is also actively involved with the Society of Petroleum Engineers (SPE) and served as the Chair for the Permian Basin Section. Shivani Vyas is technically driven and has co-authored several papers including for SPE and Artificial Lift Forums. Shivani strives to make a positive impact through her vision, technical skills, and services.

Simon Suarez holds a Bachelor of Science Degree in Mechanical Engineering from the Universidad del Zulia in Maracaibo, Venezuela. He was also a Fulbright Scholarship recipient from 2009-2011 and attained a Master of Science in Mechanical Engineering degree from the University of Houston. He brings over 15 years of expertise and knowledge from a variety of roles within the Energy industry environment. His vast international and multiple business and leadership experiences makes him a strong addition to any team.

Simon began his career in 2007 working as a Sales & Applications Engineer with Weatherford. Since then, he held multiple technical and leadership roles in Artificial Lift Systems (ALS) operations, sales, and product line management in Midland, Houston, Venezuela, Mexico and throughout Latin America. In 2019, he became Weatherford’s Global Business Director for Production and in 2021 he joined Silverwell as their Western Hemisphere Sales Director.

Emmanuel Alaeze was born and raised in South Korea where he attended an American international school from grades 1-12. His favorite subjects are history and literature, but Emmanuel also has a love for physics and an aptitude for math. Emmanuel is an engineering student at UTPB where he loves learning new things and staying curious about the world around him.

Additional Information & Resources

Please email info@alrdc.com with any inquiries.

Click the + to expand each section and view more information below.

Bush Convention Center

105 N Main St

Midland, Texas 79701

(432) 687-8250

Venue Website | Map

Accommodation

There are several accommodation options available for workshop participants:

DoubleTree By Hilton Hotel Midland Plaza

117 West Wall Street

Midland, Texas 79701

(432) 683-6131

Hotel Website | Map | Reserve a Room

Home2 Suites by Hilton Midland East

4104 N Big Spring St.

Midland, Texas 79705

(432) 682-6000

Hotel Website | Map | Reserve a Room

SpringHill Suites by Marriott Midland Odessa

5716 Deauville Boulevard

Midland, Texas 79706

(432) 682-6000

Hotel Website | Map | Reserve a Room

Townplace Suites Midland South/I-20

912 Crump Street

Midland, Texas 79701

(432) 682-6000

Hotel Website | Map | Reserve a Room

Holiday Inn Express and Suites-Midland Loop

5309 West Loop 250

North Midland, Texas

(432) 520-3600

Hotel Website | Map | Reserve a Room

Holiday Inn Express Midland South

900 Crump Street

Midland, Texas

(432) 695-9020

Hotel Website | Map | Reserve a Room

Midland, TX – Area Information

Website

How to Register as a Sponsor

Visit the Sponsorship page on the ALRDC website to review Sponsorship packages.

How to Redeem Complimentary Workshop Passes Included with Sponsorships

Complimentary workshop passes are included with the purchase select sponsorships, as indicated. If your purchase includes complimentary passes, you will receive a follow-up email within 3 business days of registration containing a unique promo code to be redeemed for workshop passes.

Daily meals are included with registration. Breakfast will be served from 7:00AM to 8:00AM, lunch from 12:00PM to 1:00PM, with morning and afternoon snacks available during breaks.

Each vendor may purchase up to two booths, which will be assigned side by side unless otherwise requested. Requests for specific booth locations will be considered, with priority given to registrants on a first come, first serve basis.

How to Register as an Exhibitor

Visit the Exhibitor page on the ALRDC website.

Booths will be assigned to fully registered exhibitors on a first-come, first-serve basis. Assignment will take place after exhibitor registration closes. Exhibitors will receive confirmed booth numbers by email.

Access info TBD

Pallet jacks and a fork lift are available for use on-site.

Prior to the first day of the workshop, please contact us by email at info@alrdc.com with any inquiries.

Prior to the first day of the workshop, please contact us via email at info@alrdc.com with any inquiries.

Your on-site contact for the workshop will be Ronda Brewer. Ronda can be reached by email at ronda@alrdc.com. During workshop hours, Ronda will be at the registration table.